Making oral care a relaxed and enjoyable experience in a simple way is a common philosophy of JIEYANG bigsmile. For this reason, JIEYNAG bigsmile never compromises in product design, and every small design has its thoughtful significance!

For example, the nozzle disassembly design of the JIEYANG bigsmile mini Q portable water flosser is different from the water flosser on the market. The disassembly and assembly of the water flosser nozzle on the market are mostly controlled by spring switch buttons. Press the button to place the nozzle into the nozzle mouth, then release the button to clamp the nozzle, which cannot be disassembled; Press and hold the button again to remove the nozzle.

.gif)

The R&D team of JIEYANG bigsmile also considered the disassembly and assembly of the spring button controlled nozzle during the initial development of the water flosser. However, they also considered that this type of nozzle disassembly and assembly has two drawbacks that affect the service life and experience of the water flosser:

Firstly, installing the buttons requires opening holes on the body, which increases the risk of water ingress into the body. Once water ingress occurs, it can easily corrode the metal parts inside the body, thereby affecting the service life of the water flosser.

Secondly, this type of switch is controlled by springs, and as a daily oral cleaning tool, the machine body is inevitably splashed or soaked with water. Water enters the area where the spring is placed through the gap of the button hole, and over time, the spring is easily corroded and rusted. If the spring is damaged, two situations may occur during nozzle disassembly: ① the buckle is not stable, causing the nozzle to fall off during tooth cleaning; ② The nozzle is stuck in the slot and cannot be removed.

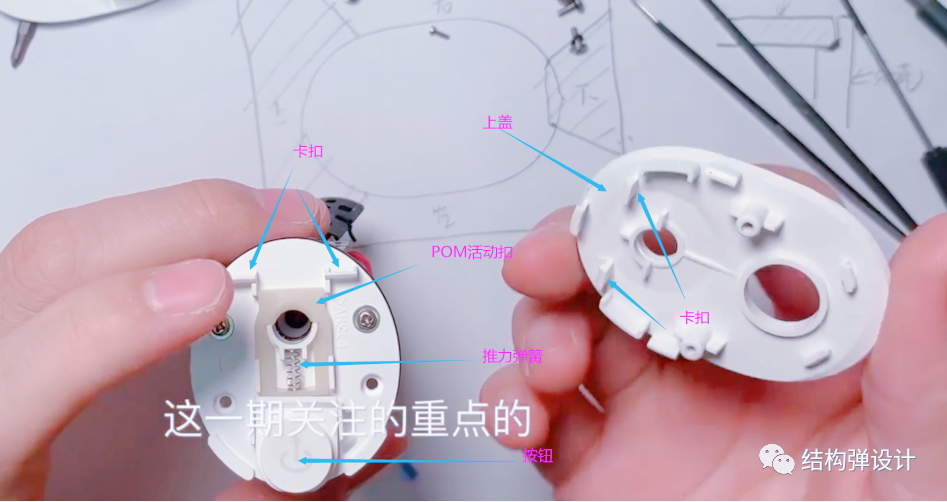

In order to prevent these shortcomings from occurring with the JIEYANG bigsmile wter flosser, the JIEYANG bigsmile R&D team conducted extensive research and designed several nozzle disassembly and assembly plans. Finally, they chose this snap on nozzle disassembly and assembly design that utilizes traditional mortise and tenon structures as the foundation design.

This design strengthens the connection through physical principles such as force transmission, friction force, material strength, and stability, without the need for any external objects or openings, and can firmly clamp the nozzle. This buckle disassembly method does not have the problem of shortening the nozzle disassembly service life caused by spring damage, and also reduces the risk of water ingress into the body, greatly improving the overall service life of the water flosser.

Insert the nozzle and rotate it 90 degrees to clamp it in place; Twist the nozzle and disassemble it in 1 second!

In terms of design, JIEYANG bigsmile will never compromise! The mini Q portable water flosser, with a high-frequency pulse design of 1400 times/minute, a 0.54mm concentrated fine water column, 5-160PSI large-span impulse selection, touch adjustable gear… Every design is meaningful, and every design is solving problems.

In the future, JIEYANG bigsmile will continue to provide more meaningful innovation, interesting, and meaningful designs to everyone, and with this as the goal, continue to work hard to speak out for China’s smart manufacturing!